Supply Food additive Gellan Gum factory

Min.Order / FOB Price:Get Latest Price

| 100 Kilogram |

Negotiable |

- Min.Order :100 Kilogram

- Purity: 85.0-108.0%

- Payment Terms : T/T

Keywords

Food additive Gellan Gum Gellan Gum factory Supply Gellan Gum

Quick Details

- Appearance:off-white

- Application:Gellan gum is widely used in foods and various other fields. (1)Typical foods prepared using gellan gum: Gelled desserts, jam, jelly, pudding, confectionery, sugarcoating of confectionery, frost of

- PackAge:25kg per drum with double pp bag inner

- ProductionCapacity:50|Metric Ton|Month

- Storage:Keep in dry and cool condition

- Transportation:by air or by sea

Superiority:

Quality: Adopting the same process with CP Kelco to assure the high quality.

Price: Offering the best price during the suppliers in China. Our factories are all over most provinces of China,including:Shandong, Baoji, Inner Mongolia and Xinjiang etc.

Rich material and energe make us control the cost effectively

Afrer-sale service: Fufeng will take charge of everthing if there is any question after the sale.

Certificates:We can offer all kinds of certificates that you need for importing. Such as: ISO9001, GMP,Kosher ,Halal,BRC etc.

Fufeng Group Company Limited is an internationalized bio-fermentation products manufacturer which is listed as a public company on the Main Board of HKEx.It is mainly specialized in the development and production of xanthan gum ,amino acids, Sodium Hyaluronate,Gellan gum and MSG etc. Fufeng group have become the largest manufacturer of Amino acids,xanthan gum and MSG in the world.

Details:

新疆阜丰生物科技有限公司

Xinjiang Fufeng Biotechnologies Co., Ltd.

Food Ingredients Gellan Gum

Gellan gum (E418) is a bacterial exopolysaccharide, prepared commercially by aerobic submerged fermentation from Sphingomonas elodea (previously called Pseudomonas elodea), in a manner similar to xanthan. discovered in 1978,1988 Approved in Japan,1992 USA full approved.

Compared with other colloids, Gellan Gum has many peculiar advantages:

1. Low dosage;

2. Excellent thermal and acid stability;

3. Good taste-releasing ability;

4. High transparency;

5. Adjustable gel elasticity and rigidity;

6. Good combinability.

Gellan gum is widely used in foods and various other fields.

(1)Typical foods prepared using gellan gum: Gelled desserts, jam, jelly, pudding, confectionery, sugarcoating of confectionery, frost of cake, filling of cake or bread, and other foods, cakes, and pet foods.

(2) Other applications:

Microbiological media, capsules, perfumes, etc.

Soft Candy Jelly

Characteristic and efficacy of Gellan Gum

|

Characteristic |

Efficacy |

|

1. Very Low dosage, form gel at 0.05-0.25% concentration |

Gellan gum is a very effective gelling agent |

|

2. Excellent thermal stability and acid stability |

1.Little effect to gel strength after heat sterilization 2.Its powder form allows longer term of use and long-term stability even under acid condition. |

|

3.Sodium or potassium irons can form thermal reversible gel, while Magnesium or calcium irons form thermal un-reversible gels |

Can be made into thermal reversible and thermal un-reversible gels |

|

4.Retains excellent flavor releasing ability |

Improve product quality |

|

5.Good combination with other hydrocolloids |

Adjustable gel elasticity and rigidity |

|

6.Good compatibility with other ingredients |

Can be widely used in many formulations |

|

7.Can form gel between pH 3.5~7.0 |

Can form high quality gels and have good gel strength in acid to neutral food formulations. |

|

8.Anti-aging function |

Prevent aging and viscosity raising of starch |

|

9.Not easy lead to enzymolysis |

Enabling flexibility in the manufacturing process, very suitable for Microbiological media and plant media. |

Antworks Capsules Culture Media Air fresher

Comestic Eye Drops Pet food Shampoo

Representative Applications of Gellan Gum

|

Function |

Application |

|

Adhesiveness |

Sugar frost, sugar coat |

|

Paint filming ability |

Succade, candy |

|

Emulsibility |

Salad cream |

|

Film forming ability |

Synthetic casing |

|

Foam stabilizer |

Beer |

|

Gelling agent |

Jelly, stuffing, dessert, fruit jam |

|

Anti-graining agent |

Frozen food, syrup |

|

Stabilizer |

Ice cream, salad cream |

Jams Jelly Beverage Icecream

Sausage Dessert Candy Noodle

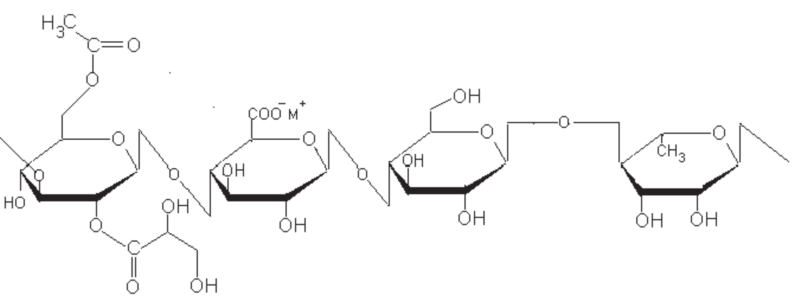

Structure of two types of gellan gum

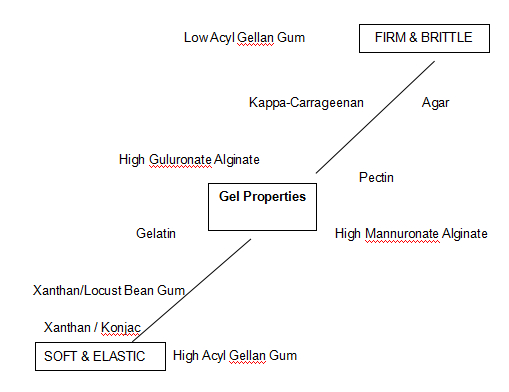

The molecular structure of gellan gum is a straight chain based on repeating glucose, rhamnose and glucuronic acid units. In its native, or high acyl form, two acyl substituents --- acetate and glycerate are present. Both substituents are located on the same glucose residue and, on average, there is one glycerate per repeat and one acetate per every two repeats. The high acyl form produces soft, elastic, non-brittle gels, whereas the low acyl form produces firm, non-elastic, brittle gels.

Structure of Native or High Acyl Gellan Gum

Structure of Low Acyl Gellan Gum

Comparison of Physical Properties of High Acyl and Low Acyl Gellan Gum

|

|

High Acyl Gellan Gum |

Low Acyl Gellan Gum |

|

Molecular Weight |

1~2×106 Daltons |

2~3×105 Daltons |

|

Solubility |

Hot water above 70℃ |

Hot water above 80℃ or cold water with sequestrants |

|

Sensitivity to cations |

Relatively insensitive to ions |

Very sensitive to ions, especially to divalent cations such as calcium ions |

|

Gelling conditions |

Just Cooling ( do not need cations ) |

Cations, acids or soluble solids |

|

Set temperature |

70~80℃ (158~176℉) |

30~50℃ (86~122℉) |

|

Thermoreversibility |

Thermo-reversible |

Heat stable if using divalent

|

|

Gel texture |

Soft and elastic gels |

Hard and brittle gels |

Solution Preparation

The hydration temperature of low acyl gellan gum is very sensitive to the ionic environment and particularly sensitive to divalent ions. Low acyl gellan gum is a mixed salt and will only partially hydrate in cold deionized water. Gum hydration is further inhibited by the divalent ions in most water supplies. This inhibition makes low acyl gellan gum easy to disperse in cold water without forming lumps. Subsequently, the gum can be hydrated using sequestrants, heat or a combination of both.

Calcium sequestrants, such as citrates and phosphates, can be used to control the divalent ions. Therefore, the hydration temperature of low acyl gellan gum can be effectively controlled. Without sequestrants, low acyl gellan gum requires a temperature of 75°C (167°F) to fully hydrate the gum. However, low acyl gellan gum can be hydrated in cold soft water using 0.3% sodium citrate, as seen in the chart below.

The setting temperature, melting temperature and final gel strength of low acyl gellan gum are also affected by cations and, therefore, sequestrants. Control of low acyl gellan gum properties can be achieved by balancing sequestrants, pH and added ions.

High acyl gellan gum will swell in deionized water creating a starch-like consistency. This swelling behavior can inhibited by low levels of sodium. The use of sodium to inhibit swelling is a useful strategy for improving gum dispersion and for minimizing viscosity during processing. Heat is required to fully hydrate high acyl gellan gum. While ions affect

dispersion and particle swelling behavior, the hydration temperature of high acyl gellan gum is relatively insensitive to ions. High acyl gellan gum hydrates between 70°C and 80°C (158°F and 176°F) even in relatively high ion concentrations.

Both forms of gellan gum can be dispersed directly in milk will hydrate during normal heat processing without sequestrants.

Gum hydration is inhibited by soluble solids and low pH for both forms of gellan gum. In high solids systems, extra care must be taken to ensure that the gellan gum hydrates. In acidic environments, the pH must be above 4 for good hydration.

Hydration Temperatures of 0.25% Gellan Gum Solutions

|

Water Hardness ppm CaCO3 |

Added sodium Citrate % |

Hydration Temperature ℃ |

|

|

|

|

Low Acyl |

High Acyl |

|

0 |

0 |

75 |

71 |

|

100 |

0 |

88 |

73 |

|

200 |

0 |

> 100 |

75 |

|

200 |

0.3 |

24 |

70 |

|

400 |

0.3 |

35 |

70 |

Gel Formation

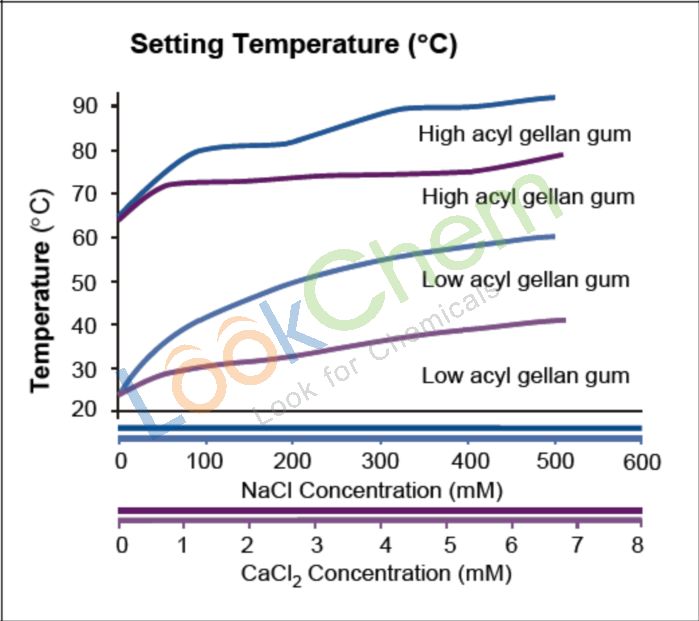

Gellan gum solutions form gels on cooling. The setting temperature will depend on the grade of gellan gum, which cations are present and their concentration, and the presence of other dissolved solids.

In the absence of added cations, low acyl gellan gum gels set at around 25ºC (77ºF), where high acyl sets at around 65ºC (149ºF). With added calcium or sodium ions, the setting temperature increases.

Low acyl gellan gum typically forms gels in the range of 30 - 50ºC (86 - 122ºF), while high acyl gellan gum normally forms gels at around 70ºC (158ºF). Gellan gum sets very quickly, as soon as the setting temperature has been reached. This is known as “snap” setting.

High acyl gellan gum forms a gel simply on cooling. Low acyl gellan gum, however, requires cations, acid, soluble solids or some combination of these additives. Divalent cations such as calcium and magnesium are the most effective for gel formation, but sodium and potassium will also work to form a gel. To optimize gel properties, it is sometimes necessary to add extra cations. Optimization is often accomplished by adding a soluble calcium salt. To avoid localized gelation, the cations are best added when the solution is hot. The solution then gels on cooling.

Low Acyl Gellan Gum Fluid Gels

Gellan gum “fluid gels” are weak gelling systems that have been subjected to shear either during or after the gelation process. The application of shear disrupts normal gelation and results in smooth, homogeneous, pourable "structured liquids". These fluid gels are extremely efficient at suspending a variety of materials, including fruit pulp, insoluble minerals used for fortification, herbs and spices, and novelty gelled beads.

Fluid gels can be produced using very low levels of Low acyl gellan gum with the appropriate levels of ions. Optimum levels of ions allow a minimum gellan gum use level. At ion concentrations above and below the optimum ion levels, increased levels of gellan gum are required.

Table 1 provides a guide to formulating fluid gels in both water- and milk-based systems.

|

Ionic concentration |

Recommended gellan gum concentration |

|

Low calcium (<50ppm) |

0.1 - 0.3% |

|

Low sodium (<0.25%) |

0.1 - 0.3% |

|

Optimum sodium (0.5 -2.0%) |

up to 0.05% |

|

Optimum calcium (100 - 600ppm) |

up to 0.05% |

|

High calcium (>0.05%) |

0.05 - 0.2% |

|

High sodium (4.0 - 10.0%) |

0.05 - 0.2% |

|

Milk |

0.05 - 0.2% |

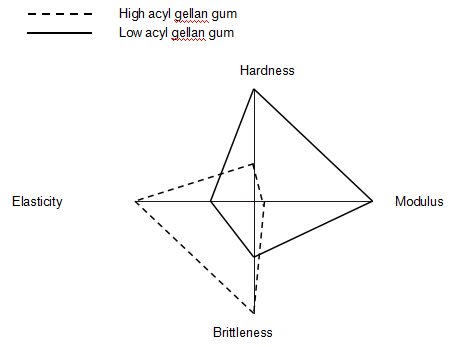

Gel Texture

One of the most important features of a gelling agent is the texture it provides. Low acyl gellan gum forms hard and brittle gels. High acyl gellan gum forms soft and elastic gels.

Gel Texture Parameters for Low Acyl and High Acyl Gellan Gum

Texture Profile Analysis uses a gel tester to compress a gel specimen twice in succession. The following parameters are measured:

Hardness The maximum force that occurs during the first compression cycle. It usually corresponds to the rupture strength of the gel.

Modulus The perceived firmness when the gel is squeezed by a small amount. It is analogous to the gentle squeezing of a fruit to test ripeness.

Fracture Strain A measure of how the gel can be compressed before it ruptures. A low number is indicative of high brittleness.

Springiness A measure of how much the gel springs back after the first compression cycle. A high number is indicative of a high degree of elasticity.

You Might Also Like

-

Gellan gum, Good Suspending ,gelling, Food ingredients

CAS NO:71010-52-1

-

Gellan Gum for sale producer global

CAS NO:71010-52-1

-

High purity Gellan Gum in stock plant

CAS NO:71010-52-1

-

Gellan gum vegetarian suppliers/wholesaler

CAS NO:71010-52-1

-

Hot sale Cosmetic Raw Material Gellan Gum in China

CAS NO:71010-52-1

-

Buy Pharmaceutical Grade Gellan Gum from manufacturer

CAS NO:71010-52-1

Related Searches

About|Contact|Cas|Product Name|Molecular|Country|Encyclopedia

Message|New Cas|MSDS|Service|Advertisement|CAS DataBase|Article Data|Manufacturers | Chemical Catalog

©2008 LookChem.com,License: ICP

NO.:Zhejiang16009103

complaints:service@lookchem.com Desktop View