- Min.Order :1 Metric Ton

- Purity: 99.90%

- Payment Terms : L/C,D/A,D/P,T/T,

Keywords

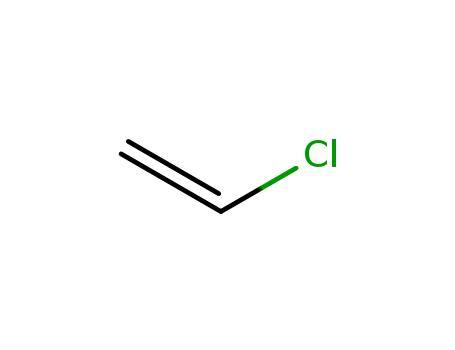

Poly(vinyl chloride) 9002-86-2 vinyl chloride

Quick Details

- Appearance:solid or liquid

- Application:for pharma use

- PackAge:drum and bag

- ProductionCapacity:1|Metric Ton|Day

- Storage:in sealed air resistant place

- Transportation:by sea or air

Superiority:

high purity lowest priceOverview

Properties: It is thermoplastic, insoluble in water, gasoline and ethanol, expandable or soluble in ether, ketone, fatty chlorohy-drocarbons or aromatic hydrocarbons with strong anti--corrosiveness, and good dieletric property.

Features: White powder, it will appear different physical and mechnial properties after add various additives to it. It has better quality of mechanic feature, anticorrosion, dielectric and anti-chemcials.

PVC Resin is the most widely raw material used in plastic production. It has good chemical stability, corrosion resistance and water resistance. It can be dissolved in acetone, hydrochloric ether, ester and some alcohol. It can offer good solubility, good electrical insulation, thermo plasticity and membrance forming capacity.

Quality standard: It's complied to the standard GBT5761-93

Applications:

SG1: it is popular use in the production of advanced electroplating insulate material etc.

SG2: it is popular use in the production of advanced electroplating insulate material, membrane, common soft products etc.

SG3: it is popular use in the production of advanced electroplating insulate material, agricultural film, leathered super surface film, all-plastic sandal etc.

SG4: it is popular use in the production of industrial and agricultural film, flexible tube, leatheroid and high-strength tube etc.

SG5: it is popular use in transparent products, hard tube, hard article, filament sleeving shaped material etc.

SG6: it is popular use in the manufacturing the material of record and transparent slice, for the production of hardboard, welding rod and fiber etc.

SG7: it is popular use in manufacturing the material of bottle and transparent, for the production of hard injection tube and perchloro-ethylene resin etc.

Specification

|

Type: |

SG1 |

SG2 |

SG3 |

SG4 |

SG5 |

SG6 |

SG7 |

SG8 |

|

K value |

77-75 |

74-73 |

72-71 |

70-69 |

68-66 |

65-63 |

62-60 |

59-55 |

|

Viscosity, ml/g |

156-144 |

143-136 |

135-127 |

126-119 |

118-107 |

106-96 |

95-87 |

86-73 |

|

Average polymerization |

|

|

1350-1250 |

1250-1150 |

1100-1000 |

950-850 |

950-850 |

750-650 |

|

Number of impurity particle max |

30 |

30 |

30 |

30 |

30 |

30 |

40 |

40 |

|

Appearing density g/ml min |

0.42 |

0.42 |

0.42 |

0.42 |

0.42 |

0.45 |

0.45 |

0.45 |

|

Residual after sieve 0.25mm mesh max |

2.0 |

2.0 |

2.0 |

2.0 |

2.0 |

2.0 |

2.0 |

2.0 |

|

0.063mm min |

90 |

90 |

90 |

90 |

90 |

90 |

90 |

90 |

|

Number of grain/400cm2 max |

40 |

40 |

40 |

40 |

40 |

40 |

40 |

40 |

|

Plasticizer absorbency value of 100g resin |

25 |

25 |

25 |

22 |

19 |

16 |

14 |

14 |

|

Whiteness % min |

74 |

74 |

74 |

74 |

74 |

74 |

70 |

70 |

|

Residual chlorethylenecontent mg/kg max |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

|

Ethylidene chloride mg/kg max |

150 |

150 |

150 |

150 |

150 |

150 |

150 |

150 |

Picturers

Details:

for pharmaceuticalOverview

Properties: It is thermoplastic, insoluble in water, gasoline and ethanol, expandable or soluble in ether, ketone, fatty chlorohy-drocarbons or aromatic hydrocarbons with strong anti--corrosiveness, and good dieletric property.

Features: White powder, it will appear different physical and mechnial properties after add various additives to it. It has better quality of mechanic feature, anticorrosion, dielectric and anti-chemcials.

PVC Resin is the most widely raw material used in plastic production. It has good chemical stability, corrosion resistance and water resistance. It can be dissolved in acetone, hydrochloric ether, ester and some alcohol. It can offer good solubility, good electrical insulation, thermo plasticity and membrance forming capacity.

Quality standard: It's complied to the standard GBT5761-93

Applications:

SG1: it is popular use in the production of advanced electroplating insulate material etc.

SG2: it is popular use in the production of advanced electroplating insulate material, membrane, common soft products etc.

SG3: it is popular use in the production of advanced electroplating insulate material, agricultural film, leathered super surface film, all-plastic sandal etc.

SG4: it is popular use in the production of industrial and agricultural film, flexible tube, leatheroid and high-strength tube etc.

SG5: it is popular use in transparent products, hard tube, hard article, filament sleeving shaped material etc.

SG6: it is popular use in the manufacturing the material of record and transparent slice, for the production of hardboard, welding rod and fiber etc.

SG7: it is popular use in manufacturing the material of bottle and transparent, for the production of hard injection tube and perchloro-ethylene resin etc.

Specification

|

Type: |

SG1 |

SG2 |

SG3 |

SG4 |

SG5 |

SG6 |

SG7 |

SG8 |

|

K value |

77-75 |

74-73 |

72-71 |

70-69 |

68-66 |

65-63 |

62-60 |

59-55 |

|

Viscosity, ml/g |

156-144 |

143-136 |

135-127 |

126-119 |

118-107 |

106-96 |

95-87 |

86-73 |

|

Average polymerization |

|

|

1350-1250 |

1250-1150 |

1100-1000 |

950-850 |

950-850 |

750-650 |

|

Number of impurity particle max |

30 |

30 |

30 |

30 |

30 |

30 |

40 |

40 |

|

Appearing density g/ml min |

0.42 |

0.42 |

0.42 |

0.42 |

0.42 |

0.45 |

0.45 |

0.45 |

|

Residual after sieve 0.25mm mesh max |

2.0 |

2.0 |

2.0 |

2.0 |

2.0 |

2.0 |

2.0 |

2.0 |

|

0.063mm min |

90 |

90 |

90 |

90 |

90 |

90 |

90 |

90 |

|

Number of grain/400cm2 max |

40 |

40 |

40 |

40 |

40 |

40 |

40 |

40 |

|

Plasticizer absorbency value of 100g resin |

25 |

25 |

25 |

22 |

19 |

16 |

14 |

14 |

|

Whiteness % min |

74 |

74 |

74 |

74 |

74 |

74 |

70 |

70 |

|

Residual chlorethylenecontent mg/kg max |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

|

Ethylidene chloride mg/kg max |

150 |

150 |

150 |

150 |

150 |

150 |

150 |

150 |

Picturers

You Might Also Like

-

D-fructose 1,6-bis(dihydrogen phosphate)

CAS NO:488-69-7

-

CAS:83-44-3 Deoxycholic acid

CAS NO:83-44-3

-

Factory supply Tetracaine hydrochloride cas 136-47-0

CAS NO:136-47-0

-

CAS:5086-74-8 Tetramisole hydrochloride factory sales

CAS NO:5086-74-8

-

Hot sell 99%min man sex powder Hongdenafil/Acetildenafil cas no 831217-01-7

CAS NO:831217-01-7

-

D-Glucosamine hydrochloride with best price and top quality

CAS NO:66-84-2

Related Searches

About|Contact|Cas|Product Name|Molecular|Country|Encyclopedia

Message|New Cas|MSDS|Service|Advertisement|CAS DataBase|Article Data|Manufacturers | Chemical Catalog

©2008 LookChem.com,License: ICP

NO.:Zhejiang16009103

complaints:service@lookchem.com Desktop View