flame retardant Potassium perfluorobutanesulfonate

Min.Order / FOB Price:Get Latest Price

| 1 Kilogram |

Negotiable |

- Min.Order :1 Kilogram

- Purity: 99% min

- Payment Terms : L/C,D/P,T/T

Keywords

Potassium perfluorobutanesulfonate High Purity Potassium perfluorobutanesulfonate 99% Potassium perfluorobutanesulfonate

Quick Details

- Appearance:pale yellow powder

- Application:Used as a flame retardant for PC

- PackAge:as you required

- ProductionCapacity:500|Metric Ton|Year

- Storage:dry ventilated area

- Transportation:courier delivery, air cargo or shipping

Superiority:

PPBS is extremely effective as a flame retardant additive with premium performance in polycarbonate at very low additive levels. PPBS has been found to be an effective flame retardant in polycarbonate at use levels as low as 0.06%~0.08% by weight. It is chemically and thermally stable to temperatures greater than 450℃,making it suitable for use in engineering resins that require high provides excellent performance without affecting the processability of the resin.

One advantage of the low use levels necessary to provide effective flame retardance is that PPBS flame retardant additive can be formulated to produce optically-clear, haze-free grades of polycarbonate for extrusion and molding. What's more, PPBS additive does not contain any bromine or chlorine and has been found effective as a flame retardant without the use of synergists.

For most effective incorporation it is recommended that the additive be initially dispersed into a 10% or more masterbatch and then compounded into the final plastic blend. Dispersion can be achieved effectively with typical polycarbonate processing equipment.

Details:

KPBS is extremely effective as a flame retardant additive with premium performance in polycarbonate at very low additive levels. PPBS has been found to be an effective flame retardant in polycarbonate at use levels as low as 0.06%~0.08% by weight. It is chemically and thermally stable to temperatures greater than 450℃,making it suitable for use in engineering resins that require high provides excellent performance without affecting the processability of the resin.

One advantage of the low use levels necessary to provide effective flame retardance is that PPBS flame retardant additive can be formulated to produce optically-clear, haze-free grades of polycarbonate for extrusion and molding. What's more, PPBS additive does not contain any bromine or chlorine and has been found effective as a flame retardant without the use of synergists.

For most effective incorporation it is recommended that the additive be initially dispersed into a 10% or more masterbatch and then compounded into the final plastic blend. Dispersion can be achieved effectively with typical polycarbonate processing equipment.

You Might Also Like

-

flame retardant Potassium perfluorobutanesulfonate

CAS NO:29420-49-3

-

Supply Tetrabromobispenol A Bis(2,3-Dibromopropyl Ether) (BDDP) manufacturer

CAS NO:21850-44-2

-

Dimethyl Methyl Phosphonate (DMMP)/756-79-6 manufacturer /supplier

CAS NO:756-79-6

-

Dimethyl methylphosphonate

CAS NO:756-79-6

-

Tetrabromobisphenol A bis(dibromopropyl ether)

CAS NO:21850-44-2

-

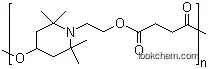

Light Stabilizer 622

CAS NO:65447-77-0

Related Searches

About|Contact|Cas|Product Name|Molecular|Country|Encyclopedia

Message|New Cas|MSDS|Service|Advertisement|CAS DataBase|Article Data|Manufacturers | Chemical Catalog

©2008 LookChem.com,License: ICP

NO.:Zhejiang16009103

complaints:service@lookchem.com Desktop View