Purity 99.1% Laser direct structuring additive dicopper hydroxide phosphate/Copper(II) hydroxide phosphate

Min.Order / FOB Price:Get Latest Price

| 1 Kilogram |

FOB Price: USD 65.0000 |

- Min.Order :1 Kilogram

- Purity: 99.1%

- Payment Terms : L/C,D/A,D/P,T/T,Other

Keywords

dicopper hydroxide phosphate purity 99.1% Copper(II) hydroxide phosphate 9 laser marking additive for LDS

Quick Details

- Appearance:GREENISH powder

- Application:The invention of the circuit board in the early 20th century revolutionized the world.Lts flat construction, however, has breakthough in ciruit board manufacuring came at the end of the 20th century w

- PackAge:CARTON

- ProductionCapacity:1000|Kilogram|Day

- Storage:

- Transportation:Without any special requirements

Superiority:

Details:

Product Description

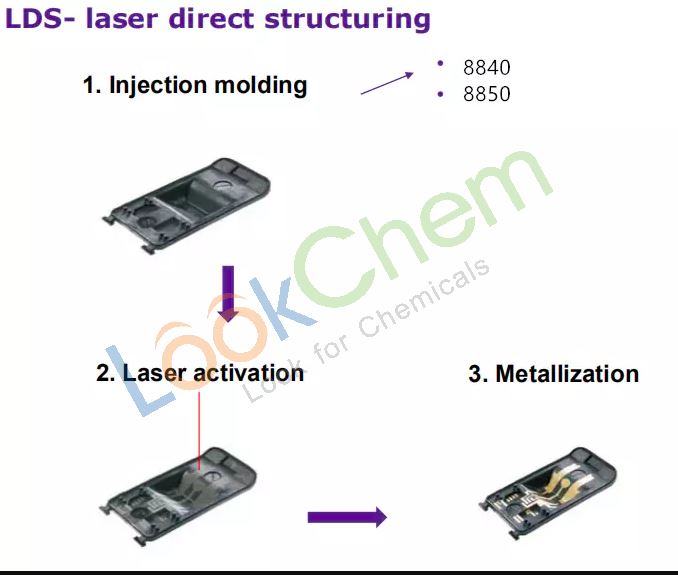

The invention of the circuit board in the early 20th century revolutionized the world.Lts flat construction, however, has breakthough in ciruit board manufacuring came at the end of the 20th century with the creation of the three-dimensional mechatronic intergrated device (3D MID). 3D MIDs enable mechanical, electronic, optical and thermal functions to be integrated into dark-colored injection-molded components. Now the evolution continues: With laser pigments from the 8840 or 8850 ,3D MIDs can be fabricated in light colors to give you a world of freedom and flexibility in the product design of electronic appliances.

Injection molding.

The produced as a single-component injection mold using commercially available thermoplastics that contain additive from Puls 8840,8850.

laser activation.

A laser beam activates the thermoplastics material and creates metallic seeds through a physical-chemical reaction.In addition to activation,the laser beam inscribes the cricuit layout directly onto the plastic component. It forms a microrough surface onto which the copper is frimly anchored during the metallization phase.

Metallization.

Metallization of the component begins with a cleaning phase. For the next step, an additive track build-up takes place in acopper bath, typically in the range of 3 to 6 um/h. Finally, a deposition of nickel and a thin layer of gold generally occurs.Application-specific coatings such as tin,silver,palladium/gold and an organic solderability preservative(OSD) also can be applied during this process. The 3D MID is ready for assembly.

You Might Also Like

Related Searches

About|Contact|Cas|Product Name|Molecular|Country|Encyclopedia

Message|New Cas|MSDS|Service|Advertisement|CAS DataBase|Article Data|Manufacturers | Chemical Catalog

©2008 LookChem.com,License: ICP

NO.:Zhejiang16009103

complaints:service@lookchem.com Desktop View